Please note that the login data for the reSTART SMES Training offer is linked to our community i.e., you don’t need to create a new user to access our training offer if you are part of the reSTART SMES community

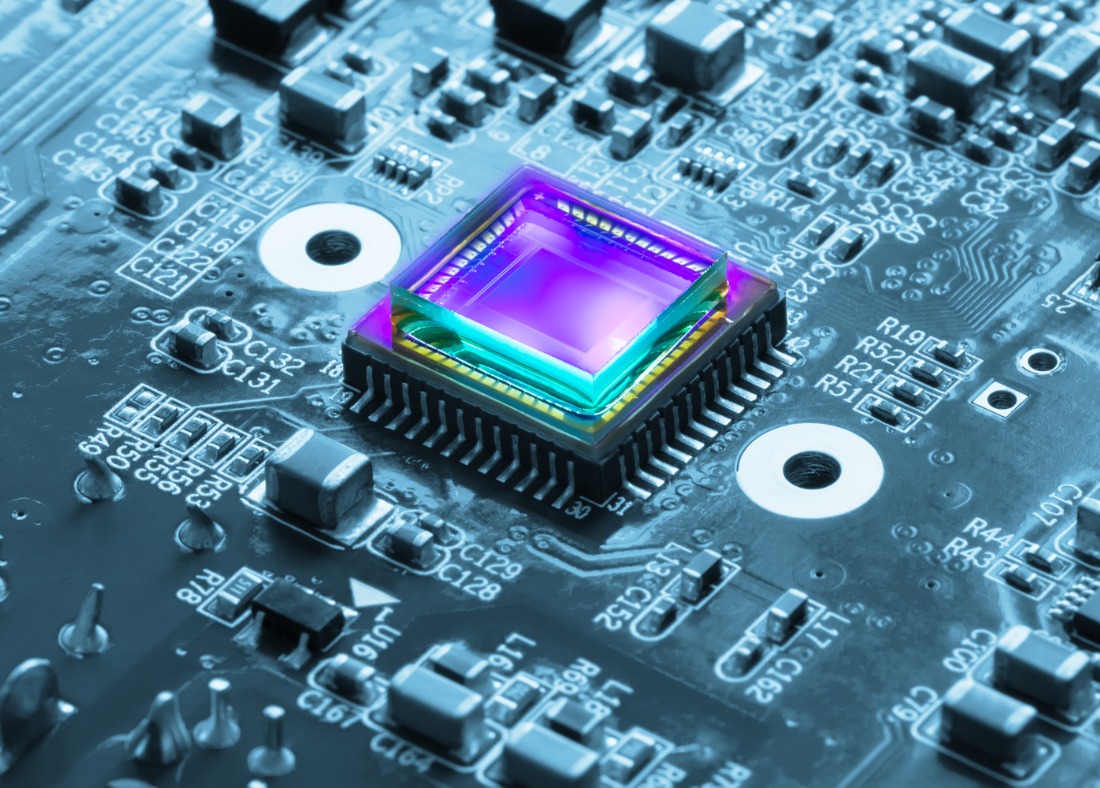

Sensors and Sensor Networks in Digital Manufacturing

Beginner

About

Green digitalization; Digital readiness; Smart manufacturing; Sensors; Smart sensors; Application

Description

Today, the manufacturing industry is aiming for a sustainable growth via management and improvement of the existing major manufacturing factors, such as productivity, quality, delivery and flexibility. This paradigm, also known as Smart Manufacturing, uses a collection of cutting-edge technologies that support effective and accurate engineering decision-making in real time.

Access

Product Tracking (Performance and Regulatory Aspects)

Level

Proficient

About

Data and connectedness; Digital readiness; Green digitalization; Product tracking; Data; Implementation; Regulation

Description

Product tracking is the process of monitoring and logging production data related to specific products so the data collected can be analysed to improve productivity, quality, and regulatory compliance. This session details why product tracking is important, example areas for implementation, methods of tracking, and discusses specific regulatory concerns for high-value manufacturing industries.

Access

Preventive, Corrective and Predictive Maintenance Systems

Expert

About

Data and connectedness; Digital readiness; Green digitalization; Maintenance, Preventive maintenance, Predictive maintenance

Description

New environments have forced managers and engineers to optimize all the systems that intervene in the production process in order to meet the requirements their clients. In this session we will cover an introduction to the maintenance process, describing its objectives and key advantages, as well as its different strategies.

Access

Metrology Assisted Assembly

Expert

About

Intelligence and automotation; Data and connectedness; Green digitalisation; Industrial robots; Metrology Assisted Assembly

Description

No manufacturing equipment is completely accurate; there will always be imperfections and inaccuracies. This is true from precision CNC machines to large industrial robots. However, it may be possible for equipment to operate at greater levels of accuracy when combined with data from metrology equipment – equipment that measures such as laser scanners or CMM machines. This technique – called metrology assisted assembly – is possible at all product scales, but has the most effect on larger products.

Access

Fusion of knowledge-driven and data-driven approaches for improved sensor analytics

Expert

About

Data-driven AI, knowledge-driven AI, machine learning, semantic technologies, dynamic dashboards

Description

Artificial intelligence (AI) plays an increasingly important role in various aspects of our lives. Also for companies emerging AI applications lead to a competitive advantage for the early adopters embracing these technologies.

Fusing data-driven and knowledge-driven AI approaches accelerate the economic potential of these technologies.

In this session we will explore what this fusion means for companies, and we will show how expert knowledge can be embedded in your AI solution to improve predictive performance.

Access

Manufacturing System Analysis

Beginner

About

Manufacturing System Analysis, Production rate, Production capacity, Production

Description

Understanding the performance of manufacturing systems is key to optimising their productivity and maximising generated revenue. Though simulations and modelling tools can achieve these goals, more fundamental analysis of production systems with formulae may lead to insights with less cost and effort.

This session is not intended to cover all possible manufacturing analysis methods, but to give examples of one set of approaches to calculating production rates and utilisation.

Access

Queuing Theory

Proficient

About

Queuing Theory, Production lines, Product-flow, Kendall’s notation, M/M/1, Markov Chains

Description

Manufacturing typically involves multiple steps as parts flow between machining stations and assembly processes on the shop floor. Unless you’re using a pulse flow production line where everything moves between stations in sync (see Session AMS 1.3 Large Scale Assembly) it is inevitable that parts will arrive at stations before the station is ready, or stations will be ready before parts are available. Using and understanding queues and the flow of parts will aid in understanding and optimising the production line.

Access

Digital Twin Concept

Expert

About

Digital twins, Manufacturing Applications, Categorization, Elements, Challenges

Description

In this session we introduce the concept of digital twins – real time simulations of manufacturing systems connected to the real thing. Currently, there is no standard definition for a digital twin, so we start by discussing the different definitions which currently exist. We then consider the different types of digital twins which exist and continue to discuss the basic elements of a digital twin, how they work, their current limitations, and current applications.

Access

Quality Strategies and Technologies in Digital Manufacturing

Beginner

About

Data and connectedness, Quality control, Strategies, Technologies, Methodologies

Description

Quality is the measure of how well products fit their intended purpose and satisfy the needs of the customer. Analysis of data will be described in other sessions to help with maintaining quality, but this session introduces the concepts and strategies to achieving the highest levels of quality.

Access

Modelling Tools and Software

Leader

About

Modelling, Simulation, Techniques, Interoperability, Tools and Software, Manufacturing system changes

Description

In modern manufacturing, product design and manufacturing rely on computer-aided design (CAD) and computer-aided manufacturing (CAM) software tools. However, the link between CAD/CAM product design and process planning is still weak due to the difficulty of matching characteristics of the product design to the required manufacturing processes, and matching those processes to available equipment capabilities.

Access

Intelligent Decision Making

Proficient

About

Data and connectedness, Decision Making, Process, Decision Support Systems, Implementation

Description

Effective decision-making is critical in manufacturing enterprises, and selecting the correct course of action can be the difference between a successful and competitive enterprise, and falling behind the competition. This session discusses the decision-making process, and how it can be made more intelligent and data-driven for easier and more effective selection of actions.

Access

Data and Data Analysis

Expert

About

Data and connectedness, Data Processing Cycle, Data collection, analysis, visualisation, interpretation, storage

Description

The process of decision making was discussed in session AMS 4.2 Intelligent Decision Making. However, making effective and correct decisions requires access to high quality data that has been correctly analysed and presented. This session discusses the data processing cycle, and the methods and challenges for the use of data and data analysis.

Access

Process Optimization by Data Mining and Machine Learning

Leader

About

Data and connectedness, Data mining, KPIs, Machine learning, Production process optimization, Transparency

Description

Modern sensing systems are making the collection of data from manufacturing systems increasingly easy, but most data collected is never analysed or actioned. However, this data could be used to optimise manufacturing processes if used correctly. This session discusses methods to evaluate manufacturing processes, and ways to use collected data to maximise these key performance indicators.

Access

Cybersecurity and the Internet of Things

Beginner

About

Cybersecurity, IoT, Decentralised Digital Identity, Distributed Ledgers, Computing Systems

Description

In an increasingly interconnected ICT ecosystem, cybersecurity has become a critical aspect of the protection of personal data and critical infrastructures. The Internet of Things (IoT) is one of the emerging technologies that is revolutionizing the way we interact with the digital world. However, IoT also presents new challenges for cybersecurity. In this presentation, we will explore the impact of IoT in the web 3 ecosystem and the challenges it poses for cybersecurity.

Access

Big Data for Industry 5.0

Proficient

About

Data and connectedness, Big Data, Industry 5.0, Data management, Cloud Storage

Description

This webinar introduces the viewer to Big Data in the edge-cloud continuum. It explains high level data gathering and management concepts, and different methods of storing large amounts of data in the cloud. The Spark framework is introduced as a solution for batch and streaming processing, and the advantages of big data analysis are discussed in terms of improved business processes and customer experience.

Access

Workforce Evolution in I4.0 + Skills 4.0. Key Professional Competencies

Conscious

About

Human centric digitalization, key professional competences, skills 4.0, digital industry workers

Description

In this session we discuss how the workforce may evolve due to Industry 4.0 and we list a set of key professional competences and soft-skills that will be increasingly important for the change adaptation of digital industry workers.

Access

Team Management and Collaborative Teamwork in the Connected Industry

Beginner

About

Human centric digitalization, teamwork, leadership, collaborative, connected industry

Description

Companies must be aware that they need to take into account people ready to take on and develop the changes brought by the digital revolution. Therefore, the objective is to generate an integral approach, through a strategic consideration, and implement tools that allow people and organizations contributing to the achievement of companies to the Industry 4.0 model.

In this module we are going to focus on the management of people empowering multidisciplinary collaborations and we are going to learn how to offer multiple learnings, so that professionals can develop their knowledge and at the same time can collaborate with other technological specialties and technologies.

Access

2023 predictions: ICS cyber threats

Proficient

About

Cybersecurity, Cyberthreats, CyberRisk, Kaspersky, Threatprotection

Description

Cybersecurity is becoming increasingly critical for organizations and individuals in an interconnected world. With advancing technology, the complexity and number of cyber threats also increase. This presentation will analyze cyber threat predictions for 2023, discussing emerging trends and challenges that organizations and individuals will need to face to protect their data and privacy.

Access

Life Long Learning Strategies, Paradigms for I4.0

Proficient

About

Human centric digitalization, Lifelong learning, 3L, learning techniques, training, professional development

Description

Companies must be aware that they need to take into account people ready to take on and develop the changes brought by the digital revolution. Therefore, the objective is to generate an integral approach, through a strategic consideration, and implement tools that allow people and organizations contributing to the achievement of companies to the Industry 4.0 model.

In this module we are going to focus on the management of people empowering multidisciplinary collaborations and we are going to learn how to offer multiple learnings, so that professionals can develop their knowledge and at the same time can collaborate with other technological specialties and technologies.

Access

ERP systems interoperability

Beginner

About

Digital transformation; ERP; interoperability; manufacturing software; Industry 4.0; MRP; MES

Description

Session to introduce the digital transformation conceptual bases and how it can help manufacturing companies achieve their strategic goals: Why is it necessary? How to do it? Which benefits does it provide?

The session also makes special emphasis on information systems. It debates about the areas that need to be digitalized, what digitalizing them involves and how an ERP implementation process needs to be planned.

Finally, some topics about sustainability in digital transformation are being introduced.

Access

Industrial IoT

Beginner

About

Digital readiness; Internet Of Things; connectivity; sensors; monitoring; digital twins

Description

This training gives a high level overview of the industrial Internet Of things. It touches upon the definition of IoT, the most popular application areas, and gives some example use cases. The training goes a bit deeper into the crucial components that every Industrial IoT system should have and also lists some challenges that are associated with its deployment. To conclude, an overview is given of the different categories of wireless technology that could be used to deploy an Industrial IoT platform.

Access

Cyber Physical Production Systems and Industrial Robots

Beginner

About

Intelligence and automotation; Cyber Physical Systems; Cyber Physical Production Systems; Intelligent Robotics; Robotics; Industrial robots; Mechanical structures

Description

This session reviews the basics of Cyber Physical Production Systems (CPPS) and robotics to provide the reader with an introduction about Intelligent Robotics.

Access

Safety: Industrial Standards and Equipment

Expert

About

Intelligence and automotation Intelligent Robotics; Robotics; Safety; Industrial standards; Industrial equipment; Risk assessment; Risk reduction; Control system requirement; Collaborative robots

Description

The session describes the hazard related to robots and the main standards for the safety of robots. Starting from the general norms and standards applicable to machines, risk reduction process and performance level of control systems are addressed.

Access

Human-Robot Collaboration

Proficient

About

Intelligence and automotation; Human-robot; Collaboration; Intelligent Robotics; Robotics; Human centered factories

Description

The session deals with a new trend of industrial robots, based on a more integrated collaboration with human operators. The migration from complementary to collaborative operations between humans and robots enables the improvement of efficiency, flexibility, and safety.

Access

Robotic Applications

Leader

About

Intelligence and automotation; Intelligent Robotics; Robotics; Application; Mechanical structures; Industrial robots; Additive manufacturing

Description

This session gives an overview on the specifications and requirements for industrial robotics in different application domains, analysing some of the most widespread applications. At the end of the session a special focus is given on industrial robot applications in welding and some more recent developments, such as in additive manufacturing-based processes.

Access

Cloud Technology for Industry 5.0

Level

Beginner

About

Data and connectedness, software architecture, edge computing

Description

This webinar provides an introduction to cloud concepts and the network edge. The high-level differences between off- and on-premise clouds are explained, as well as the costs and benefits of edge computing. Well-known cloud infrastructure providers are introduced, and a three step process is explained to move from classic software architectures to microservices in the cloud, running on powerful orchestration software. The concepts are illustrated with the use of a high-level use case.

Access

Artificial Intelligence for Industry 5.0

Level

Beginner

About

Intelligence and automation, artificial intelligence, cloud, edge computing, industry 5.0

Description

This webinar provides an introduction to practical AI applications for Industry 5.0. The different uses of cloud AI and edge AI are elaborated, highlighting their respective benefits and potential for synergy. Predictive applications are shown to reduce downtimes, optimize maintenance schedules and avoid unexpected costs, while AI optimization can improve individual machines, entire production chains, and simulate the manufacturing and performance of new products. The synergy of these applications is illustrated with a high-level use case.

Access

Connectig data, AI and Blockchain in manufacturing

Level

Beginner

About

Data and connectedness, DLT, data, Machine Learning, AI, Blockchain

Description

This training will start by providing an overview of the current data market to further explain the role of AI and Blockchain in connecting data and unlocking its potential, especially in the manufacturing sector. The expert will also give an insight into CoLearn, a decentralized machine learning platform based on a distributed ledger, and built by Fetch.AI, that enables anyone to share or exchange data securely.

Access

The path to AI in manufacturing

Level

Proficient

About

Data and connectedness, I4.0, AI, data, digital manufacturing, use case

Description

While AI is very well known also in the context of Industry 4.0, profitable and scalable business cases are still rare. This video will explain what can be expected from this technology and what the conditions are for a profitable use case. The expert will also give an insight into i-flow, a solution to minimize the effort for tedious integration of machines, plants and sensors into IT systems and I4.0 use cases and eliminate complex data handling tasks on the shop floor.

Access

Challenges and Keys for a Successful Digital Transformation

Level

Beginner

About

Digital strategy, transformation, technology, Industry 4.0

Description

Digital transformation marks a radical rethinking of how an organization uses technology, people and processes to radically change business performance. Digital transformation requires collaboration between different departments. This is the path to pairing business-focused philosophies with rapid application development models. Such sweeping changes are typically undertaken in pursuit of new business models and new revenue streams, often driven by changes in customer expectations around products and services. During this session, you will understand in further detail the challenges and the key actions that a company must take into account in order to carry out a successful digital transformation.

Access

Introduction to Industry 4.0

Level

Conscious

About

Digital strategy, transformation, technology, Industry 4.0, basics

Description

Now, more than ever, companies are navigating an era of profound change. Compared to earlier industrial revolutions, the so-called fourth industrial revolution or Industry 4.0 (I4.0) encompasses not just one but a combination of disruptive technologies (e.g. artificial intelligence, additive manufacturing, cloud computing and cybersecurity – amongst many others) moving at breakneck speed and providing unparalleled transformations across multiple industries.

Access

Digital Transformation: Why so much hype?

Beginner

About

Digital strategy, Industry 4.0, Digitization, Digitalization, Digital Transformation

Description

Businesses have always been evolving and innovating, new technologies have always come with challenges and opportunities, and ecosystems have always been changing. So what makes the current era of technological change so different?

It’s in the degree of interconnectedness, speed of acceleration of change and the very nature of the change itself. Disruption isn’t new, but the speed, complexity and global nature of the disruption is at a scale never seen before.

Immerse yourself into the present session to understand the definition of and the reasons why companies should bet on digital transformation.

Access

Key Enabling Technologies Related to I4.0

Beginner

About

Digital strategy, transformation, technology, Industry 4.0, basics

Description

In Session Introduction to Industry 4.0 it was demonstrated that Industry 4.0 does not focus on a specific technology but rather on how to make use of technologies in order to achieve the main objective, i.e. the creation of adaptable, flexible and efficient smart factories capable of improving the value delivered to customers.

However, it is important to know about each of the available technologies and how these technologies can be combined in order to truly benefit from them. In this session, each of the technologies commonly defined as key drivers in Industry 4.0 will be presented.

Access

Unlocking new digital business models for production companies using Servitization

Beginner

About

Digital strategy, Servitization, data, new digital business model, networked ecosystem, digital product passport

Description

The cooperative and transparent use and linking of different machine and user data in a well-integrated ecosystem based on a standardized architecture enables the development of new solutions and business models using artificial intelligence.

In his presentation, expert Prof. Bernhard Kölmel from the applied University of Pforzheim will provide an overview of the future of products and services in the manufacturing industry.

Access

Large Scale Assembly

Expert

About

Digital strategy, Industry 4.0, Digitization, Digitalization, Digital Transformation, Advanced Manufacturing Systems, Large Scale Assembly

Description

The assembly processes of large products come with their own set of challenges and complexities. Achieving the tight tolerances and quality requirements as products get larger is a challenging process and requires specialist techniques.

For the purpose of this module, large scale assembly is the assembly of large (greater than 2m x 1m x 1m) multi-component, low batch (<100 per month) products. This module will focus on aerospace assemblies where these challenges are most acutely felt, but also includes high-value automotive assembly, ship building, and high-value construction projects with high quality requirements such as nuclear constructions or bridges.

Access

Digitalization of Supply Chain

Beginner

About

Green digitalisation, Industry 5.0, digitalisation, sustainable logistics, multimodal, route optimisation, demand forecasting, security, production planning

Description

Technological challenges and digitisation of the supply chain: As the rules of the supply chain game are changing, and the high pace of digitisation is becoming a key part of the transformation of the sector, it is imperative to be part of the change with three main pillars in mind: Managing the shift towards green digitisation; Create digitally enabled responsible logistics platforms; Putting people at the centre of the digitisation process.

Access

What is Technology Roadmapping?

Beginner

About

Digital strategy, Industry 4.0, Digitization, Digitalization, Digital Transformation, Roadmap

Description

The term technology roadmapping has gained widespread use in industry, academia and government. A technology roadmap is a high-level visual document that defines and communicates the plan for technology initiatives at the organization. A technology roadmap generally outlines why, when and what technology solutions can be implemented, aligning technological initiatives with both short and long-term business goals. In other words, a roadmap presents the consensus which has been reached regarding needs and the potential technologies required to satisfy those needs.

Access

Human-Centred Cognitive Robotics for the workplace of the future

Beginner

About

Human centric digitalization, Industry 5.0, robotics, human-centred, sustainability, resilience

Description

This session addresses the topic of Robotics within Industry 5.0, focused on people, sustainability and resilience.

The expert delves into the current situation and trends within robotics in the workplace, focusing on four main areas of specialization: Manipulation and Collaboration, Perception, Ground Robots and Aerial Robots.

During the session, numerous applied examples of robotics in these four areas of expertise are presented in both the industrial and autonomous aspects and allows us to look at the many possibilities of human-centered robotics on the workplace.

Access

Characteristics and Enabling Technologies for Reconfigurable and Flexible Assembly Systems

Proficient

About

Digital readiness, Industry 4.0, Digitalization, Digital Transformation, Manufacturing systems, Enabling technologies, Flexible Manufacturing Systems, Reconfigurable Manufacturing Systems

Description

There are many types and classes of manufacturing systems, and selecting the right type for your need is critical. In particular, use of flexible and/or reconfigurable manufacturing systems may enable your company to more rapidly adapt to changing circumstances.

Access

New Product Introduction Strategies

Beginner

About

Digital readiness, Industry 4.0, Digitalization, Digital Transformation, Manufacturing systems, Product Strategies, Product

Description

The introduction of new products to the market is a challenging time for a manufacturing enterprise. Market needs must be identified to ensure the product has a market to sell to, the product must be designed to meet functional requirements, and a production process must be designed to manufacture the product.

Access

Join the fastest growing online community for manufacturing SMEs in Europe!